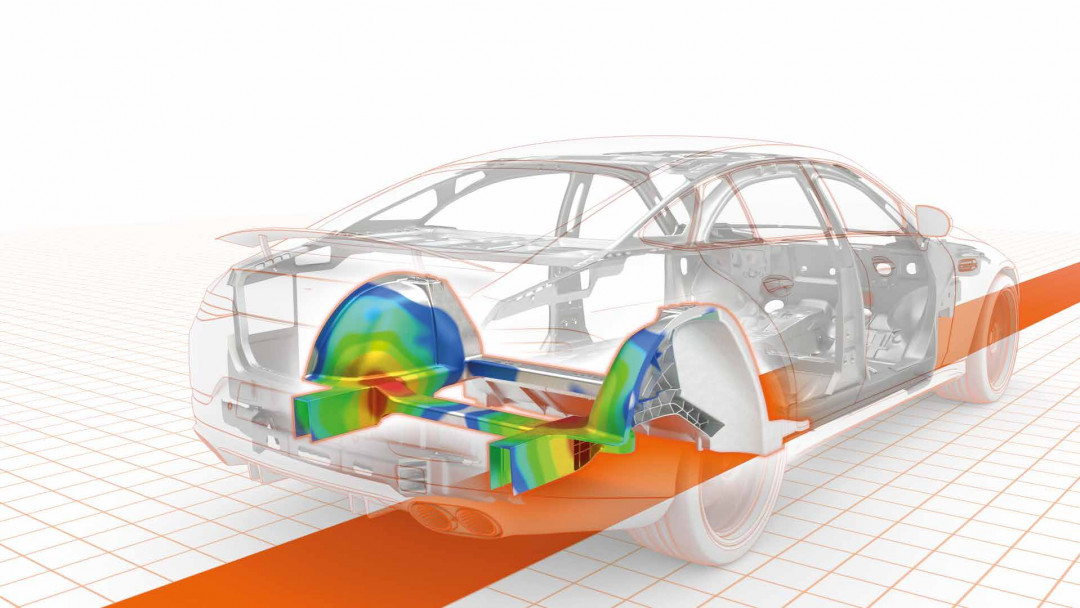

In aluminium casting, Handtmann acts as a strategic system partner, particularly for the automotive industry. With over 2000 employees, we are the largest family-owned aluminium foundry in Germany. Renowned manufacturers and suppliers have been relying on Handtmann for five generations now. They trust our highly developed process and machining expertise as well as our experience and strength. This trust pays off. As a development partner to our customers, we attach great importance to achieving their goals with them. We pool expertise, network ideas and set standards right from the start. We provide support from the idea to market maturity, using simulations, design and topology optimisation as well as additive prototype production.

Megacasting represents the next evolutionary stage in die casting. Handtmann decided early on to be the first Tier 1 in Europe to invest in this future technology. In close cooperation with our customers, we are developing innovative large cast components for the mobility of the future. Only a short time ago, megacasting was the subject of controversial debate, but at the same time Handtmann made this decision with confidence and foresight. The lightweight construction trend is a predominant topic in the die casting industry. The bodywork sector in particular offers opportunities to save weight. Megacasting and the reduction of components through large cast die-cast parts play an important role here.

At EUROGUSS 2024, we will be giving you an in-depth insight into Handtmann's decision-making process for entering the megacasting sector, both at our stand and in specialist presentations, and will show you the strategic thinking and facts that prompted us to enter this trend at an early stage. Take advantage of these opportunities and engage in a personal dialogue with our experts.

Our modern, highly automated machinery offers maximum flexibility and guarantees the precise further processing and assembly of all parts. The fascinatingly light Handtmann products of recent years - in their category - include pioneering ICE, structural and chassis components. In the interests of our customers, we invested in the transformation at an early stage: PHEV, BEV and fuel cell components from Handtmann have long been part of the programme. We are now supporting customers in their transformation, providing expertise, suitable strategies and processes. Pick up speed with us.

Our company has aligned all process chains with the transformation and developed a strategy for a successful future. We are your partner for an effective transformation process. We benefit from the synergies of light metal casting expertise, innovative development and system assembly. Thinking ahead together.

Albert Handtmann Metallgusswerk GmbH & Co. KG

Arthur-Handtmann-Straße 25 - 31

88400 Biberach/Riss

www.handtmann.de

Hall 7A, Stand 340