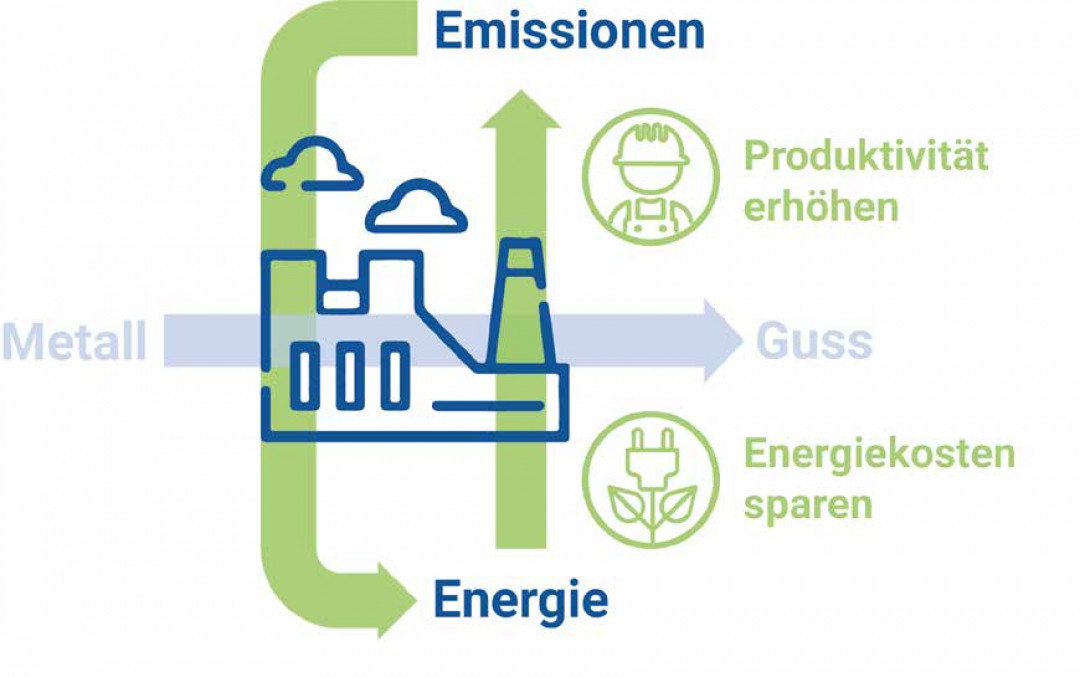

Would you like to find out how your foundry can improve its energy efficiency with modern environmental technology? As a provider of integrated solutions comprising exhaust air purification, heat recovery and heat utilisation, KMA will be presenting its entire range of environmental technology services for die casting applications at EUROGUSS 2024. The solutions presented will help foundries to successfully save energy, reduce CO2 emissions and create an attractive working environment for qualified personnel. The associated improvement in the carbon footprint can be clearly demonstrated and support you in realising your sustainability goals.

Save energy: Energy efficiency is the foundation for the competitiveness of foundries. The utilisation of process heat, efficient air management and the reduction of heating energy consumption are central starting points for measures to increase energy efficiency within the foundry. The combination of exhaust air management systems and the conservation or recovery of waste heat offers great potential and increases the economic success of the foundry. On request, KMA prepares customised operating cost calculations and determines specific potential savings in terms of energy costs and CO2 emissions.

Reducing CO2 emissions: The increasing demands placed on sustainable production sites by end customers and the successive additional costs for CO2 emissions pose challenges for foundries. With the help of energy-efficient exhaust air management and integrated heat recovery, forward-looking foundries can sustainably reduce their carbon footprint and improve their competitiveness. KMA supports foundries in achieving their individual sustainability goals and offers holistic energy analyses tailored to the various production processes. To improve the carbon footprint, not only the direct energy requirements of the casting process are evaluated, but also the energy-relevant overheads of the foundry, such as hall ventilation and hall heating, are analysed. The overall energy cost benefits can then be calculated down to the energy consumption per casting. Leading foundries can thus demonstrate their sustainable performance to customers and the public.

Increase productivity. Attracting and retaining the right talent for the company is only possible in the long term in a clean working environment with systematic exhaust air treatment. An attractive working environment not only fulfils occupational health and safety requirements, but also demonstrably increases the foundry's productivity. Clean, emission-free workplaces are evidence of responsible health management and environmental awareness towards the company's own workforce as well as a high quality standard for its own production site vis-à-vis customers.

"In order to increase energy efficiency, it is essential to take a holistic energy view of the foundry, from the casting process to the building technology. In this way, major operating cost benefits can be realised, ideally even the complete supply of the hall heating - this not only benefits the environment, but also strengthens the foundry's competitive position thanks to the sustainable reduction in energy requirements," says Dr Holger Wagner, KMA Managing Director. "We are seeing strong global interest in foundry-proven solutions for greater sustainability and efficiency. We look forward to presenting our wide range of environmental technology solutions at EUROGUSS 2024."

KMA Umwelttechnik GmbH

Eduard-Rhein-Straße 2

53639 Königswinter

www.kma-filter.de

EUROGUSS 2024: Hall 7, Stand 305