As one of the leading players in the manufacturing industry, LiCON is once again setting new standards with its pioneering technologies and state-of-the-art solutions.

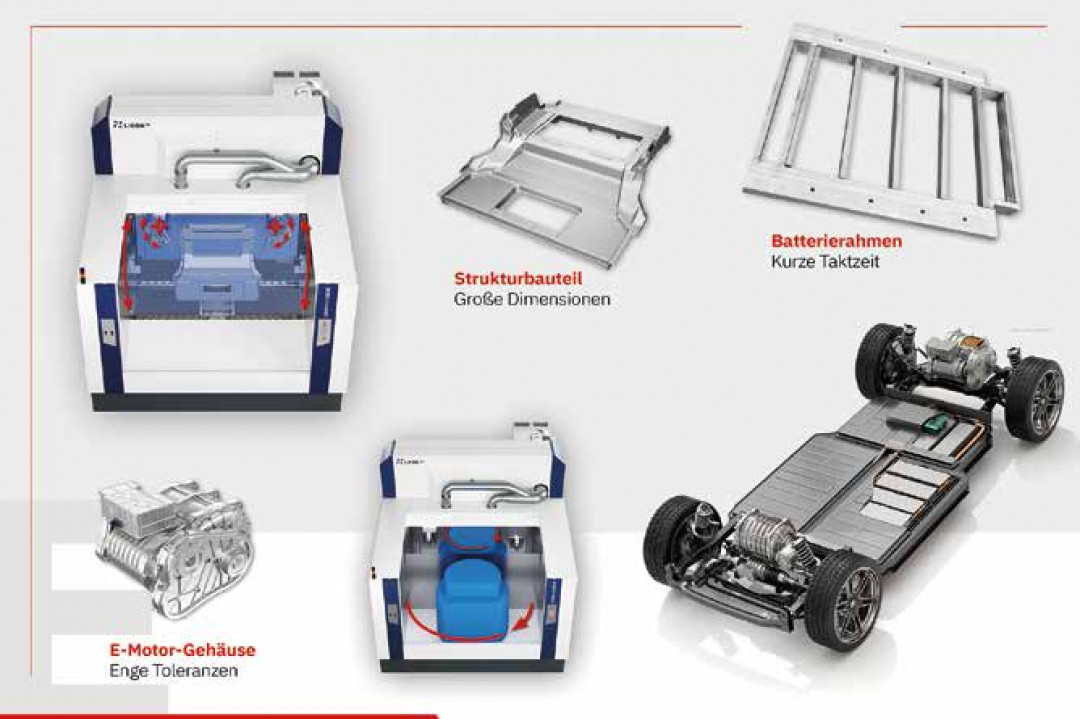

The latest upgrade of the LiFLEX machining centre product line impresses with short tool change times, minimal non-productive times, high dynamics and independent X, Y and Z axes. Spacious work areas enable complete machining in just one clamping operation. These innovations help to achieve more efficient production with pallet changers and open up new possibilities for the large-cubic machining of components such as battery frames and trays, RUB (rear underbody) and FUB (front underbody).

LiCON machining centres are characterised by short tool change times and minimal non-productive times, as the next tool in the double gripper arm is already ready to be changed. With outstanding dynamics, LiCON machining centres guarantee precise machining even for highly complex components. The high accuracy, stability and repeatability are decisive for the quality of the end products and enable the precise mechanical machining of complex components.

The i³ technology, integrated as standard in LiFLEX machining centres, allows independent correction of the two spindles in the three axes (X, Y and Z), enabling double-spindle production that is just as accurate and precise as a single-spindle machine.

With its LiFLEX machining centres, LiCON offers generous working areas with sufficient space for machining large workpieces. This enables complete machining in a single clamping operation. This eliminates the need for component handling between the machines, which avoids reclamping errors and also saves time, space and costs during direct loading. This also makes automation more cost-effective and space-saving, which further underlines the versatility and flexibility of the LiCON machining centres.

The LiCON machining centres are specially designed for the large-cubic machining of battery frames, RUB and FUB. This technology makes it possible to machine components of impressive size and complexity, which is becoming increasingly important, especially due to electromobility. In addition, the integrated pallet changers offer an automated solution to increase production efficiency. The I+I option opens up the opportunity to carry out different types of machining simultaneously with two spindles on one component, even using a swivelling spindle.

LiCON machining centres are used worldwide in the automotive industry and various other branches of industry. The international orientation gives customers worldwide access to advanced technologies, innovative strength, high quality and economical solutions.

At EUROGUSS 2024 in Nuremberg, LiCON will be presenting the latest innovations in its product portfolio at its stand.

LiCON mt GmbH & Co. KG

Im Risstal 1

88471 Laupheim

www.licon.com

Hall 9, Stand 461