Large, geometrically complex components such as die-cast aluminum parts for the automotive industry have so far been difficult to measure validly. Testing in the measuring room requires a corresponding capacity and is time-consuming; so-called gage check gauges require a certain planning, procurement and implementation time. An innovation opens up new possibilities: senswork developed the 3D measuring system ZScan, a solution that is always ready for use and provides a valid measurement result in seconds. And it does so directly in production.

By Evelyn Haid

„The investment was worth it“

This is confirmed by Rocco Hahn, Head of Project Management at Magna. It was the measuring speed and flexibility that convinced Magna of the ZScan system from senswork. The automotive supplier had been looking for an optical measuring and inspection system suitable for series production for some time when the Bavarian measurement technology expert senswork came into play. Was the investment worthwhile? "The summary is positive, definitely," say Rocco Hahn, Head of Project Management and Martin Emrich, Project Manager at Magna. The investment pays off after just a few product launches.

100 % testing in pre-series and small series

Various aluminum die-cast components can be checked for dimensional accuracy in seconds with this single system – and without any pretreatment. With this speed, ZScan goes beyond the capabilities of a mere measuring system and qualifies as a production tool. A capability study conducted by Magna, which compared the measurement results from the measuring room with those of the ZScan, confirmed its high measurement quality and the validity of the measurement results. Components can thus be considered as validly inspected by ZScan without further inspection in the measuring room. It thus offers a perfect and very flexible supplement in pre-series and small series production, in which every component leaves production 100 % IO.

Up to 76 % faster start-up time

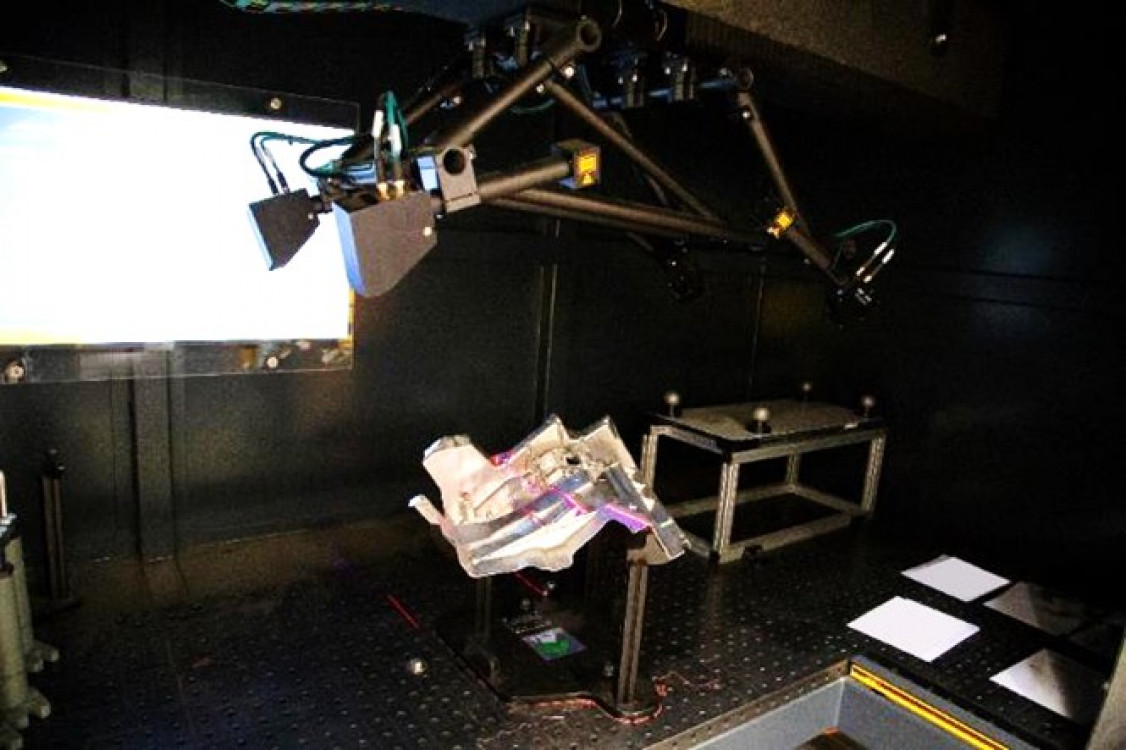

In the application, any component up to a length of 1.60 meters can be scanned with the flexible optical measuring system. Due to the component-unspecific application, processes in the start-up phase benefit in particular, precisely because the procurement of type-specific measuring equipment is no longer necessary. The investment is lower, the speed higher. Start-up times for new products can be significantly accelerated with a time gain of several weeks compared to conventional solutions.

Production tool with automatic CAD alignment

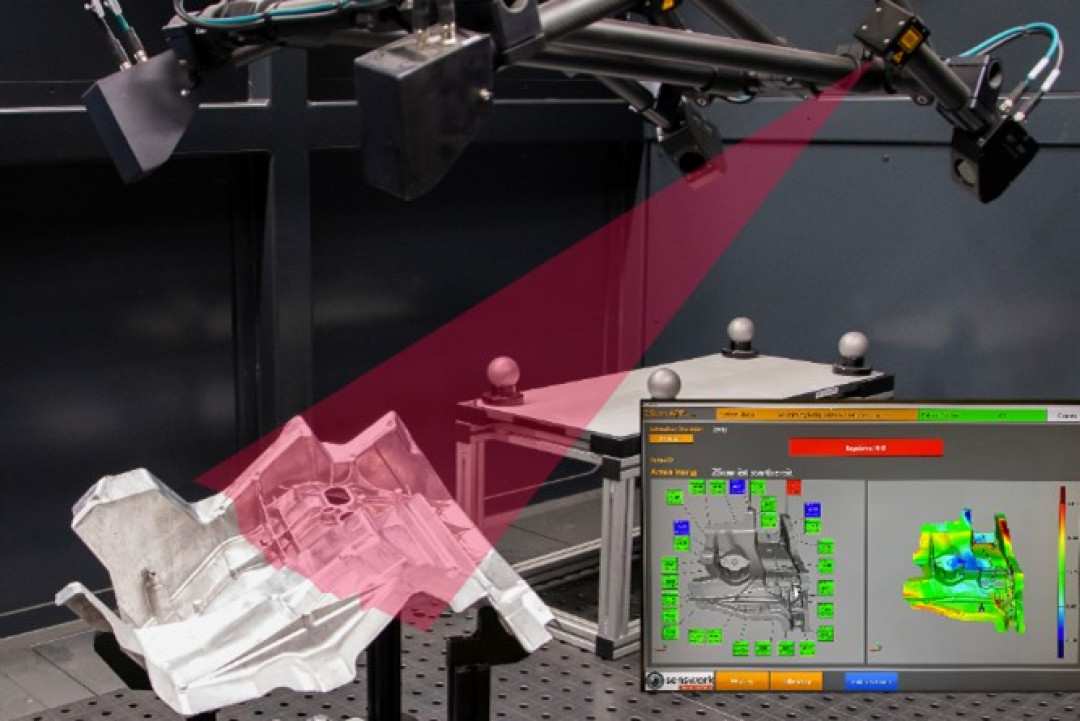

The inspection process also holds great functionality. Within a few seconds, ZScan 3D multi-sensor scanner scans the respective aluminum die-casting component and automatically compares it with its CAD model. Four laser scanners, calibrated to each other, are used in this process. Thanks to their free spatial arrangement, they can detect even geometrically complex component surfaces with virtually no shadowing. ZScan also masters slightly shiny surfaces such as aluminum effortlessly – and without any pre-treatment.

The result IO versus NIO is displayed on a panel and shown in a precise 3D false color image as a red-green comparison in a flowing color gradation. In addition, the panel visualizes a free number of measuring points, which are evaluated according to the RPS system. The dimensional measuring points are displayed in green, over- and underruns of the tolerance or deviations from the nominal dimension in red and blue. In combination with the additional quickly recognizable false color image, the workers can make targeted geometry corrections directly after the measurement process, which takes only seconds. ZScan can thus be used efficiently as a production tool with a subsequent manual straightening process. Checks between and after straightening can be performed at any time and the process can be repeated until the IO result is achieved.

See more thanks to versatile measurement functions

Straightening processes are standard in the production of structural aluminum die-cast parts as at Magna BDW. Heat treatment at almost 500 °C introduces distortions into the parts, which have to be corrected again in the downstream process based on precise specifications. This is exactly where ZScan shows its strengths with up to 20 million measuring points per single scan: The combination of preliminary RPS alignment, point-based 3D measurement and false-color CAD comparison is particularly helpful in production: "You see a lot of details that are not detected in conventional measurement. In production, this is a bit of a blessing and a curse at the same time," says Rocco Hahn, Magna, "but it has definitely been very well received by the customer. The ability to digitize parts ad hoc and compare data sets to each other is also very advantageous".

Easier process optimization

This functionality additionally offers engineers a great deal of insight with regard to process optimization. Components can be inspected before and after each production step, such as the heat treatment of aluminum die-cast parts. Individual scans can be compared with each other and dimensional deviations are visualized in different colors. This provides greater insight into production processes at every step of the process. Measurement series can be created, archived and evaluated by software with ZScan. The influence of parameter adjustments in the process is already made measurable in production. The process steps can thus be optimized in a data-based, targeted manner.

„We want to use it to produce parts and not just generate measurement quality“, adds Rocco Hahn. And there is another special feature: Not the trained measuring technician, but the worker himself operates ZScan directly in production. This allows it to be used as a production tool and at the same time saves capacity in the measuring room. "The user-friendly operation and clear component selection enables a very fast training process for new employees of about 30 minutes, so that employees on shift can look after ZScan themselves," says Martin Emrich, Magna. Any employee can also make component changes. In addition, ZScan robustly withstands the demanding production environment with dust, contamination and temperature variations.