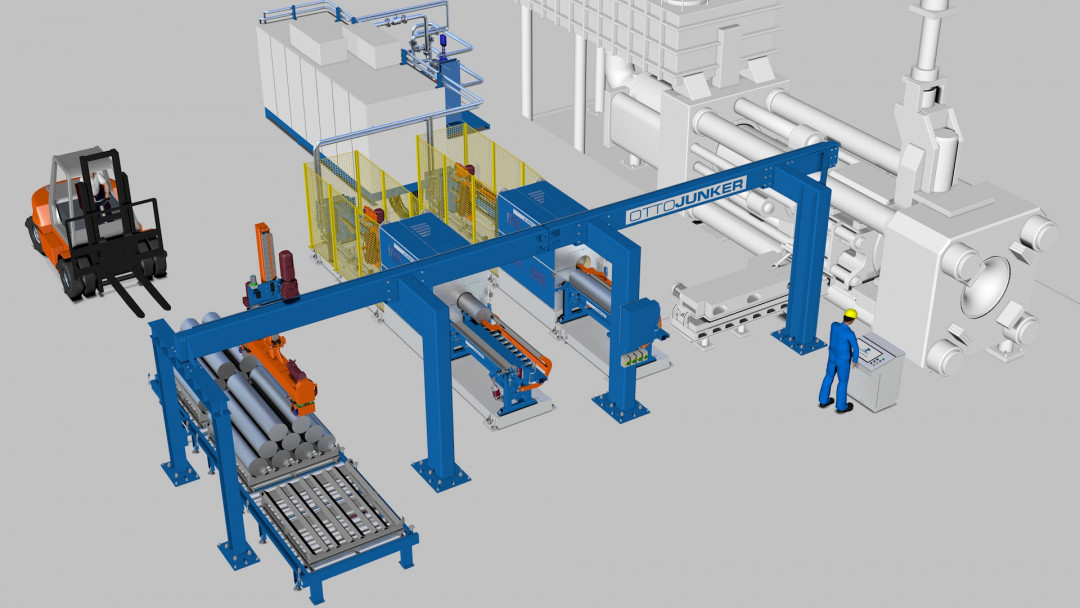

OTTO JUNKER presents two products that are helping to shape the future of metalworking: EcoJet, the newest product on the market, and JuDy, a proven solution that joins EcoJet to create an unbeatable combination. These solutions offer extremely efficient preheating of bars and billets, enable environmentally friendly heating without fossil fuels and promise minimal maintenance costs. With these furnace solutions, OTTO JUNKER offers a sustainable and cost-efficient alternative for the industry.

The EcoJet preheater is a preheating oven that combines maximum efficiency and environmental protection. With an efficiency of over 95 %, EcoJet sets new standards in the emission-free preheating of bars and billets. Thanks to decades of experience in resistance and convection heating as well as the latest technologies including state-of-the-art flow simulations and calculations, OTTO JUNKER can offer specially developed heating coils with high power density for various applications with the EcoJet preheater. The temperature is monitored using thermocouples to ensure optimum heat transfer. All components of the EcoJet preheater are the result of in-house development, design and production, which guarantees the highest quality and reliability.

By using the EcoJet preheater, companies can not only improve their ecological footprint, but also ensure their productivity in times of fluctuating gas supplies. With a fast heat-up time and precise temperature control, the oven offers a sustainable solution that combines environmental protection and economic efficiency.

The JuDy (JunkerDynamicHeater) is an induction-heated furnace that revolutionises the final heating of billets. With an efficiency of approx. 58 % and the ability to generate a precise temperature curve in the billet through individual zones, the JuDy enables highly efficient production. The use of a ceramic melting protection tube significantly reduces the energy requirement. Thanks to the OTTO JUNKER support shell transport, scratches and scoring on the stud surface are avoided. By using the mathematical process model "Billet Pilot", the amount of heat can be optimised and the heating time reduced. Both the IGBT converters and the coils are core components manufactured in-house, which are extensively tested and adjusted before delivery.

JuDy offers the necessary flexibility for special requirements and at the same time guarantees a reproducible temperature curve. This solution complements electrically heated preheating furnaces - as a stand-alone system, in parallel and in line. The highlight lies in the combination of EcoJet and JuDy, which together achieve an impressive level of efficiency.

EcoJet and JuDy are not only technological milestones, they also open up a wealth of possibilities for various branches of industry. The ovens can be used in a variety of applications to increase efficiency, minimise environmental impact and reduce costs. Example industries where significant added value can be achieved are metal processing and foundries: In the metal industry, EcoJet and JuDy can help to optimise energy consumption, speed up production processes and improve the quality of end products. This is particularly important for the production of aluminium and copper.

Renewable energies: In the fields of solar energy, wind energy and battery production, precise heating processes are of great importance. EcoJet and JuDy offer sustainable solutions for the production of components in these high-growth sectors.

Automotive industry: The automotive industry can benefit from the advantages of these innovative furnaces to precisely heat bolts and other metal parts, making the production of vehicle components more efficient and environmentally friendly.