The Maus CAAT software, developed and patent pending by Reichmann, optimizes machining programs of Maus machines in previously unattained dimensions. Initial tests confirm the software's promising potential with cycle time and productivity increases in automatic grinding in the double-digit percentage range. The software was presented to the public for the first time at this year’s GIFA trade show.

By Stefanie Henkel

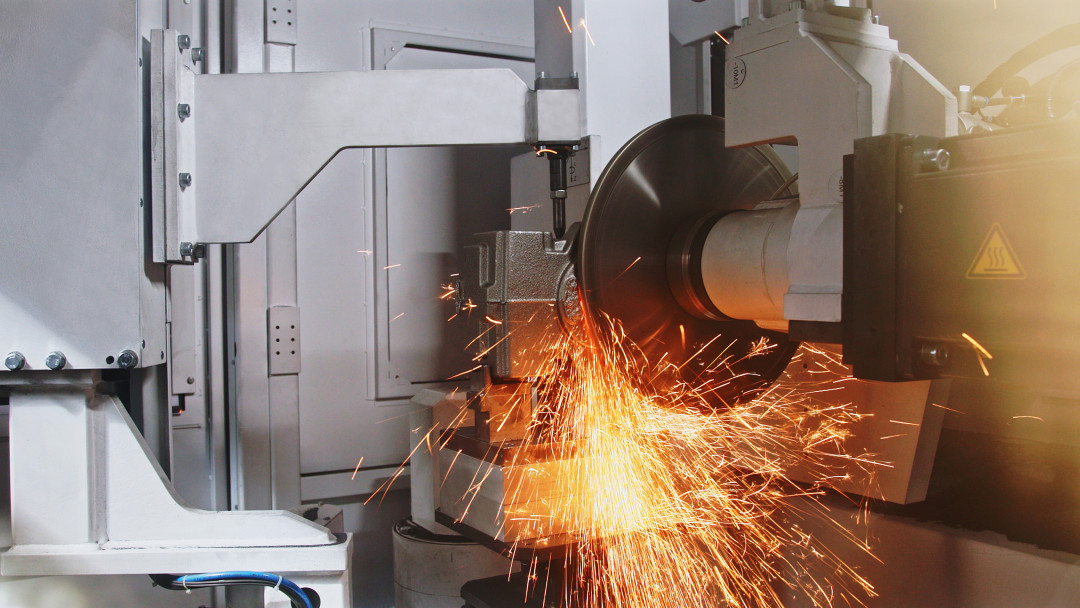

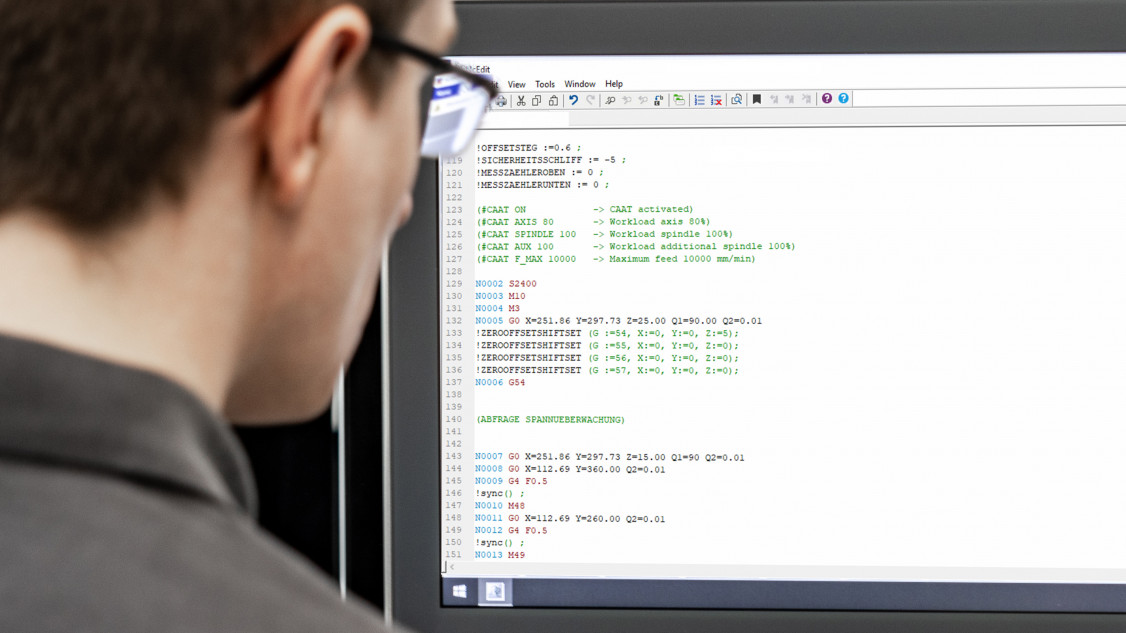

The Maus machine line already sets new standards in automatic grinding without further program optimization. The simple programming is convincing all along the line. Machining programs can be created on a Windows-based interface through intuitive teach-in with structured plain text comments (fig. 1). This reduces the time required for programming and ensures a high degree of clarity, a fast-learning curve and a high level of acceptance, especially for machine operators without prior knowledge. The high machining quality is also outstanding. The optionally available laser measurement compensates for tolerances in the tenth of a millimeter range and thus ensures finished contours.

Besides, an automated machine that is easy and safe to operate facilitates foundries to attract personnel for casting finishing tasks. This ensures that capacity is maintained in the long term and productivity can be increased. The high power density, maximum availability and robust machine design "Made in Germany" guarantee that the machine is highly economical.

Exploits previously unused potentials

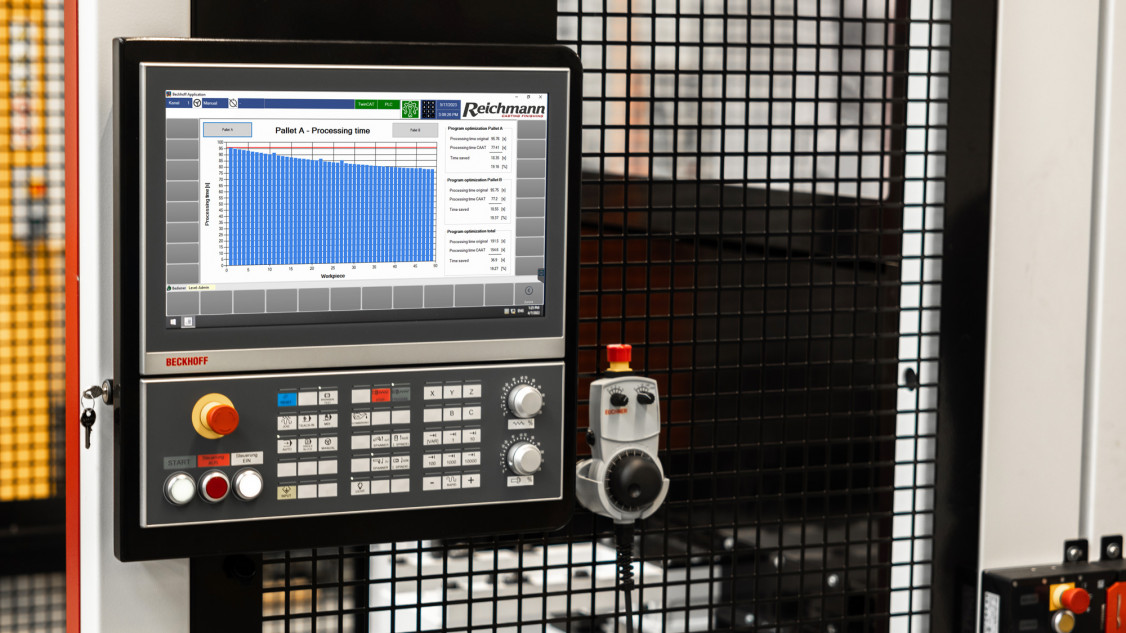

The new operating system for the Maus grinding machines offers huge potential for Industry 4.0 and 5.0 and can support the user with the help of state-of-the-art technologies such as IIoT or artificial intelligence to further increase machine performance and productivity. With the new "computer aided automatic tuning" self-optimization software for Maus grinding machines, “Maus CAAT” for short, Reichmann is taking a big first step to make use of these possibilities. For the first time, machine data such as the spindle and drive power during operation, are available to the operator in a structured form and can be used for optimizations manually and automatically.

Perfect interaction between operator and machine

The Industry 5.0 concept is about optimized interaction between operator and machine. Intelligent machines should help people to work faster and more efficiently. This is precisely where the Maus CAAT software, developed and patent pending by Reichmann, comes in.

The program code created by the machine operator for finishing a new casting is analyzed block by block with the help of Maus CAAT. During the machining process of the first castings, the software specifically detects even the smallest weaknesses and optimization potentials in the program. Wherever there is potential for increasing spindle and drive performance, the feed rate is increased iteratively. In this way, Maus CAAT optimizes the machining program in the shortest possible time to achieve top performance with maximum time savings while making optimum use of the machine's output. In addition, the software adapts the machining speed to the weight of the casting directly during machine loading. This means that relatively light workpieces can be machined even faster. This results in a perfect interplay of human and machine intelligence.

Self-optimization provides a leading edge

"In initial tests, Maus CAAT was able to speed up ready-optimized teach programs by over 15 % and provide the appropriate input to the programmer for further optimizations. That's 15 % more parts in the same time," reports Rafael Dineiger, International Sales Manager at Reichmann & Sohn GmbH (fig. 2). These accelerations would classically only be possible to a significantly limited extent using the multi-eye principle and with considerable time expenditure. "This completely new type of computer-aided, automatic optimization gives our customers a decisive lead over the competition", says Rafael Dineiger.

The easy-to-understand user interface of the Maus machines enables the machine operator to set up and use the software easily and parameter-controlled as required. Foundries that have already invested in a Maus grinding machine can save valuable time and costs with Maus CAAT by automatically optimizing the program sequences and maximize their productivity.